|

|

Ing. Tibor Dzuro, PhD. |

| |

Associate professor |

| |

|

| |

Contact: |

| |

Technical University of Košice |

| |

Faculty of Mechanical Engineering |

| |

Department of Automotive Production |

| |

Office: 158 |

| |

Floor: 1 |

| |

Adress: Mäsiarska 74, 040 01 Košice, Slovakia |

| |

Phone No.: +421 55 602 3524 |

| |

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it. |

| |

|

|

| CURRICULUM |

| 1991 - 1996 |

|

Technical University of Košice, Faculty of Mechanical Engineering |

| 1996 |

|

Mechanical engineer, field of 23-07-8 Mechanical engineering technology (Forming) |

| 2001 |

|

PhD., field of 23-07-9 Mechanical engineering technology and materials (Forming) |

| 2001 - 2006 |

|

Researcher, Department of technologies and materials |

| 2006 - 2017 |

|

Assistant professor, Department of computer support of technologies |

| 2014 |

|

University Pedagogy Course |

| 2016 |

|

Associate professor in the field 5.2.51 production technologies |

| 2017 - present |

|

Associate professor, Department of Automotive Production |

| |

|

|

| LANGUAGE SKILLS |

|

|

|

|

|

|

|

|

| |

|

|

| SCIENTIFIC ORIENTATION |

- Theoretical background of forming processes.

|

- Formability tests (material and process formability).

|

- Evaluation of limit states, forming limit diagrams.

|

- Simulation of forming processes using CAE systems.

|

- Design of forming tools using CAD systems.

|

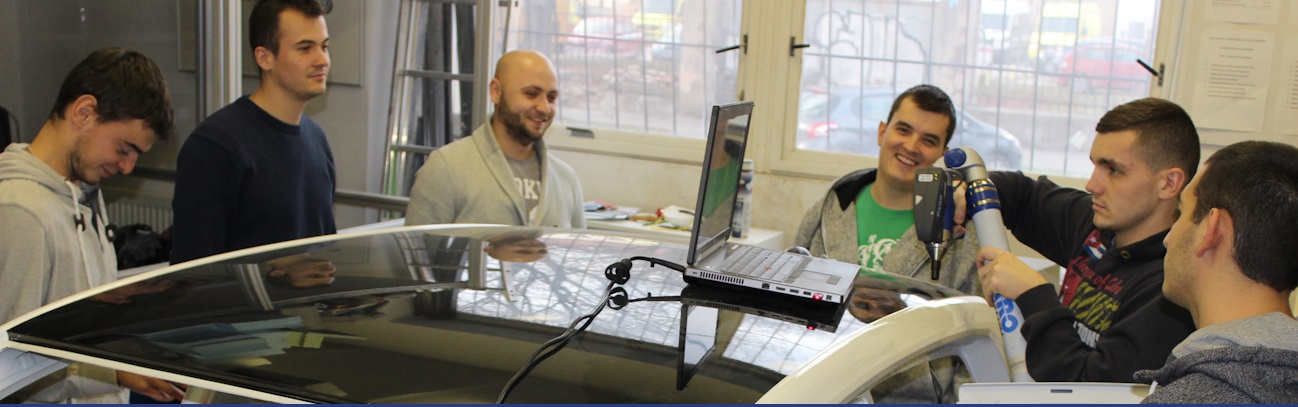

- Digitization (scanning), reverse engineering and assessment of the accuracy of stamped parts.

|

| |

|

|

| PEDAGOGICAL ACTIVITIES |

- Lectures on the subjects: Automotive production management, Fundamentals of automotive component production design, Automotive production technologies (EN).

|

- Lectures on selected chapters from the subjects: Theory of Conventional Technologies, Experimental Methods in Technologies, Information Technologies I a II.

|

- Conducting exercises in the subjects: Simulation of Production Processes (SK, EN), Information Systems for AP (SK, EN), CAE Systems in AP (SK, EN), CAx Methods in Processes Design, Theory of Conventional Technologies, Information Technologies I. and II., Forming Tools.

|

- Supervision of bachelor and diploma theses.

|

| |

|

|

| PROJECTS (COORDINATOR, CO-INVESTIGATOR) |

| VEGA, KEGA: |

- Influence of plastic deformation instability anisotropy on formability and fracture during deep drawing. Project Manager: prof. Ing. Ladislav Pollák, CSc., VEGA project No. 1/2284/95 – Co-investigator.

|

- The effect of strengthening and normal anisotropy on the primary stability of the deep drawing process. Project Manager: prof. Ing. Ladislav Pollák, CSc., VEGA project No. 1/6243/99 – Co-investigator.

|

- Research the formability limit states and stress-strain models for thin steel sheets under various stress-strain states. Project Manager: prof. Ing. Emil Spišák, CSc., VEGA project No. 1/9387/02 – Co-investigator.

|

- Theoretical-experimental analysis of the complex stability of anisotropic drawing process. Project Manager: prof. Ing. Ladislav Pollák, CSc., VEGA project No. 1/9396/02 – Co-investigator.

|

- Research on the anisotropic drawing process of complex shapes of stampings. Project Manager: Ing. Juraj Hudák, CSc., VEGA project No. 1/2201/05 – Co-investigator.

|

- Computer-aided production of complex surfaces on CNC machines for research, development and verification of tools and molds for the production of plastic automotive parts. Project Manager: doc. Ing. Ján Kráľ, CSc., VEGA project No. 1/4159/07 – Co-investigator.

|

- Research the conditions affecting the ultimate deformations of thin, surface-treated steel sheets. Project Manager: prof. Ing. Emil Spišák, CSc., VEGA project No. 1/0725/08 – Co-investigator.

|

- Verification of friction models on tool contact surfaces during deep drawing. Project Manager: prof. Ing. Emil Evin, CSc., VEGA project No. 1/0890/09 – Co-investigator.

|

- Integrating modern product design methods into the educational process. Project Manager: doc. Ing. Ján Slota, PhD., KEGA project No. 263-049TUKE-4/2010 – Co-investigator.

|

- Research and optimization of methods for evaluating the strength and plastic properties of very thin packaging sheets. Project Manager: prof. Ing. Emil Spišák, CSc., VEGA project No. 1/0396/11 – Co-investigator.

|

- Research of improving the quality of milling shaped surfaces with advanced coated tools.Project Manager: doc. Ing. Jozef Beňo, CSc., VEGA project No. 1/0500/12 – Co-investigator.

|

- Implementation of new methods and forms in the teaching of engineering technologies and materials. Project Manager: doc. Ing. Janette Brezinová, PhD., KEGA project No. KEGA 059 TUKE-4/2012 – Co-investigator.

|

- Study of tribological aspects of the formability of surface-treated sheets and tailor welded blanks. Project Manager: prof. Ing. Emil Evin, CSc., VEGA project No. 1/0824/1212 – Co-investigator.

|

- Research and optimization of the evaluation of the pressability and joinability of high-strength steel and aluminum sheets. Project Manager: prof. Ing. Emil Spišák, CSc., VEGA project No. 1/0872/14 – Co-investigator.

|

- Competency training in CNC programming. Project Manager: prof. Ing. Ildikó Maňková, CSc., KEGA project No. 070TUKE-41/2017 – Co-investigator.

|

- Innovation of the educational process in teaching CAD/CAM/CAE systems using the GRID computing cluster. Project Manager: doc. Ing. Ľuboš Kaščák, PhD., KEGA project No. 065TUKE-4/2017 – Co-investigator.

|

- Influence of laser welding parameters on the structure and properties of welded joints of modern steels for the automotive industry. Project Manager: Ing. Ján Kepič, PhD./prof. Ing. Emil Evin, CSc., VEGA project No. 2/0113/16 – Co-investigator.

|

- Application of high-strength materials for surface parts of car bodies. Project Manager: prof. Ing. Emil Spišák, CSc., VEGA project No. 1/0441/17 – Co-investigator.

|

- Prediction of weldability and formability of combined laser-welded blanks made of high-strength steels with the support of CAE systems. Project Manager: Ing. Ján Kepič, PhD./prof. Ing. Emil Evin, CSc., VEGA project No. 2/0080/19 – Co-investigator.

|

- Implementation of CAx systems and virtual engineering techniques in the redesign of car body deformation zone parts. Vedúci projektu: prof. Ing. Emil Evin, CSc., VEGA project No. 1/0238/23 – Co-investigator.

|

- Research and development of methodologies for evaluating sheet metal deformations and manufacturability of automotive components in a virtual environment. VEGA project No. 1/0609/25 – Project Manager.

|

| |

| APVV projects: |

- Design of modern steels based on formability characteristics – Project Manager: prof. Ing. Emil Spišák, CSc., project No. APVV-0629-06 – Co-investigator.

|

- Application of progressive tool coatings to increase the efficiency and productivity of sheet metal stamping from modernly designed materials – Project Manager: prof. Ing. Emil Spišák, CSc., project No. APVV-0682-11, Co-investigator.

|

- Supporting innovations in body components made from steel sheet blanks aimed at safety, ecology and reducing the weight of cars. Project Manager: prof. Ing. Emil Evin, CSc., project No. APVV-0273-12, Co-investigator.

|

- Increasing the quality of cutouts and the efficiency of cutting electrical sheets. Project Manager: prof. Ing. Emil Spišák, CSc., 2013-2017, project No. APVV-14-0834, Co-investigator.

|

- Increasing the efficiency of pressing and joining hybrid body parts. Project Manager: prof. Ing. Emil Spišák, CSc., 2018-2021, project No. APVV-17-0381, Co-investigator.

|

| |

| EU projects: |

- Research Center for the Management of Technical, Environmental and Human Risks for the Sustainable Development of Production and Products in Mechanical Engineering. Project IMTS: 26220120060 – Co-investigator.

|

- University Science Park TECHNICOM for innovative applications with the support of knowledge technologies. OP Research and Development, 2013-2015, ITMS 26220220182.

|

- Package of supplements for further education reform at TUKE. OP Education, 2013-2015, ITMS 26110230093.

|

- Universities as engines of development of the knowledge society (CVTI SR). OP Education, 2013-2015, ITMS 26110230120.

|

- Research into a new generation of materials, structures and technologies for 21st century industry, OP Research and Innovation, 2016-2019, ITMS 313011T594.

|

- Starter package of investment elements for LLL at TUKE, OP Human Resources, 2018-2021, ITMS 312011F928.

|

| |

|

|

| FOREIGN STAYS |

| 2008 |

|

MECAS-ESI, Plzeň, Czech Republic. |

| 2012 |

|

MCAE Systems, Kuřim, Czech Republic. |

| 2019 |

|

Development center ŠKODA Auto, Mladá Boleslav, Czech Republic. |

| |

|

|

| THE MOST IMPORTANT PUBLICATIONS |

| [1]. TOMÁŠ, M. - NÉMETH, S. - EVIN, E. - HOLLÝ, F. - KUNDRACIK, V. - KULYA, J. M. - BUBER, M.: Comparison of Friction Properties of GI Steel Plates with Various Surface Treatments. Spôsob prístupu: http://dx.doi.org/10.3390/lubricants12060198... - 2024. In: Lubricants. - Bazilej (Švajčiarsko) : Multidisciplinary Digital Publishing Institute Roč. 12, č. 6 (2024), s. [1-13] [online]. - ISSN 2075-4442 (online). |

| Databases: WOS SCOPUS CCC Quartile: WOS: Q2, SCO: Q1 Impact factor: 3.90 |

| |

| [2]. TOMÁŠ, M. - EVIN, E. - KEPIČ, J. - HUDÁK, J.: Physical Modelling and Numerical Simulation of the Deep Drawing Process of a Box-Shaped Product Focused on Material Limits Determination. Spôsob prístupu: https://www.mdpi.com/2075-4701/9/10/1058... - 2019. In: Metals. - Basel (Švajčiarsko) : Multidisciplinary Digital Publishing Institute Roč. 9, č. 10 (2019), s. [1-16] [online]. - ISSN 2075-4701 (online). |

| Databases: WOS SCOPUS CCC Quartile: WOS: Q2, SCO: Q1 Impact factor: 3.90 |

| |

| [3]. EVIN, E. - TOMÁŠ, M. - NÉMETH, S.: Numerical and Experimental Analysis of Stress–Strain Characteristics in DP 600 and TRIP 400/700 Steel Sheets. Spôsob prístupu: http://dx.doi.org/10.3390/ma17010210... - 2024. In: Materials. - Bazilej (Švajčiarsko) : Multidisciplinary Digital Publishing Institute Roč. 17, č. 1 (2024), s. [1-25] [online]. - ISSN 1996-1944 (online). |

| Databases: WOS SCOPUS CCC Quartile: WOS: Q2, SCO: Q1 Impact factor: 3.90 |

| |

| [4]. EVIN, E. - TOMÁŠ, M.: Influence of Friction on the Formability of Fe-Zn-Coated IF Steels for Car Body Parts. Spôsob prístupu: https://doi.org/10.3390/lubricants10110297... - 2022. In: Lubricants. - Bazilej (Švajčiarsko) : Multidisciplinary Digital Publishing Institute Roč. 10, č. 11 (2022), s. [1-17] [online]. - ISSN 2075-4442 (online). |

| Databases: WOS SCOPUS CCC Quartile: WOS: Q3, SCO: Q1 Impact factor: 3.20 |

| |

| [5]. TOMÁŠ, M. - BUBER, M. - KULYA, J. M. - SULAČEK, J. - EVIN, E. - FABIAN, M.: Pressings shape evaluation by modern contactless methods. Spôsob prístupu: https://doi.org/10.36547/ams.31.1.2107... - 2025. In: Acta Metallurgica Slovaca. - Košice (Slovensko) : Fakulta materiálov, metalurgie a recyklácie Roč. 31, č. 1 (2025), s. 42-46 [print]. - ISSN 1335-1532.. |

| Databases: WOS SCOPUS CCC Quartile: WOS: Q3, SCO: Q1 Impact factor: 3.10 |

| |

|

|