The employment of graduates of the study programme AUTOMOTIVE PRODUCTION

Graduates of the bachelor study programme Automotive Production will be employed as production technologists, designers of jigs and tools, workers in CAx technology departments, specialists for testing, operation and maintenance, especially in the supply sector of the automotive industry, in the development of components, production management in automotive service and other activities related to automotive industry. They may also find employment in lower-level management units, technical departments of plants and factories, and may also be members of management units of larger organisations.

Graduates of the master study programme Automotive Production have a wide range of jobs in automotive production, in research and development centres of automotive companies and suppliers of aggregates and components, in production preparation units and as designers of production processes and systems. They work as production engineers capable of ensuring the quality and efficiency of production and its continuous innovation. The Automotive Production study programme is designed to prepare mechanical engineers for the creation of new products, designing production processes and managing the production of automobiles and their components. The graduate has knowledge and competence to use them in the areas of component production technologies, assembly of aggregates and cars and their testing, production techniques, structure of production workplaces, logistics and organisation of automotive supply chains. The content of the programme is implemented through teaching in order to provide theoretical, research, professional and practical knowledge throughout the innovative trends of automotive production. Graduates are equipped with the knowledge to create new and innovative products especially computer-aided design and construction techniques, virtual reality, prototyping and testing. They are proficient in lean and agile manufacturing methods and high technology implementation. The graduate profile also includes knowledge of a foreign language and adequate knowledge of economics, management, environmental science and safety. Graduates have additional knowledge on the basis of which they are able to work in a team with other professions participating in the provision of production (marketing, service, logistics, etc.).

The Department guarantees the study programme in the field of Automotive Production.

Guaranteed study programmes in the field of AUTOMOTIVE PRODUCTION

Bachelor's study programme - 1st degree

The graduate of the Bachelor's degree programme will acquire the ability to:

-

- acquire the ability to creatively solve tasks focused on innovative technology designs,

- will be able to design variants of production workplaces and plants,

- will be able to solve the concept of interconnection of material and information flows in the production system,

- will be able to apply information technology and computer support tools in the design of jigs and tools in the technological preparation of production, production planning and management and in testing,

- will deal with the specifics of the development of automobiles and their components, their production, management of supply networks, testing and operation.

Graduate employment

Graduates of the study programme will be employed as production technologists, designers of jigs and tools, workers in CAx technology departments, specialists for test laboratories, operation and maintenance, especially in the supply sector of the automotive industry, in the development of components, production management in automotive service and other activities related to automotive industry. They may also find employment in lower-level management units, technical departments of plants and factories, and may also be members of management units of larger organisations.

Master's degree programme - 2nd degree

Graduates of the Master's degree programme will acquire the ability to:

- solve complex problems in the field of calculations, design and verification of structures using modern numerical, experimental and simulation methods , including information technology

- analyse and understand design, technological and organisational processes in engineering, specialising in the automotive industry,

- specify, design, implement and maintain integrated innovative solutions in the creation, production and operation of automotive technology,

- manage product, technology and management change processes in the light of globalisation, shortening innovation cycles, technological developments and increasing demands on productivity, quality and the economics of production,

- work on projects involving problem identification, analysis, design and implementation of large-scale production system solutions, together with testing and documentation, applying the various aspects of quality as well as their environmental impact,

- Work effectively as an individual, as a member and as a team leader,

- keep in touch with developments in his/her discipline with continuous self-development.

Graduate employment

Graduates are employed in a wide range of professions in automotive production, in research and development centres of automotive companies and suppliers of aggregates and components, in production preparation units and as designers of production processes and systems. They work as production engineers capable of ensuring the quality and efficiency of production and its continuous innovation. The Automotive Production study programme is designed to prepare mechanical engineers for the creation of new products, designing production processes and managing the production of automobiles and their components. Graduates have the knowledge and the ability to apply it in the areas of component production technologies, assembly of aggregates and cars and their testing, production technology, the structure of production workplaces, logistics and the organisation of automotive supply chains. The content of the programme is implemented through teaching so that theoretical, research, professional and practical knowledge is provided throughout the innovative trends in automotive production. Graduates are equipped with the knowledge to create new and innovative products, in particular computer-aided design and construction techniques, virtual reality, prototyping and testing. They are proficient in lean and agile manufacturing methods and high technology implementation. The graduate profile also includes knowledge of a foreign language and adequate knowledge of economics, management, environmental science and safety. Graduates have additional knowledge that enables them to work in a team with other professions involved in production support (marketing, service, logistics, etc.).

PhD. study programme - 3rd degree

Graduates of the 2nd degree of the study programme Automotive Production have the opportunity to continue their doctoral studies in the related field of "Mechanical Engineering Technologies and Materials".

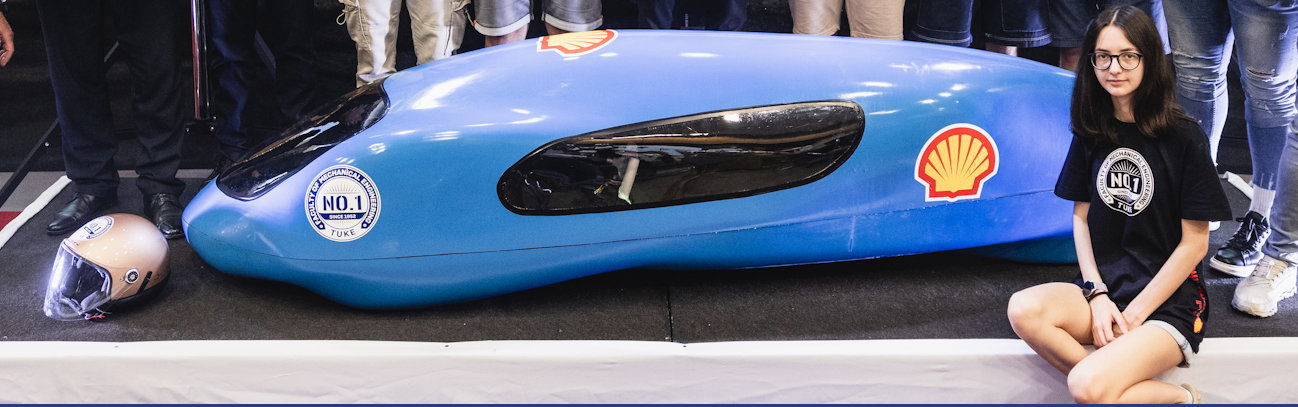

As a leisure activity, students in grades 1, 2 and 3 can take part in building a car as part of the "Car for the future" project.

The Department of Automotive Production (DoAP) is a part of the Institute of Technological and Materials Engineering of the Faculty of Mechanical Engineering of the Technical University in Košice. Currently, the teaching area of the department is focused on the study programme Automotive Production. The subjects are mainly focused on technologies and processes of automotive and automotive components production, product design and innovation, testing and certification. It includes the application of CAx technologies in both product design and manufacturing processes and workplaces.

Research and development within our workplace is oriented to technology, product design, automotive production organization, application of lean manufacturing and assembly methods and tools.

Education and training of students focusing on the preparation of professionals for the positions of project manager, fixtures, jigs and products designer, process engineer and test engineer in the automotive industry. Graduates will gain knowledge in the field of automotive production management (economics and production management, quality management and logistics in the automotive industry).

The research is focused on the construction of ultra-lightweight cars using alternative energy sources, development and application of new advanced metallic, polymeric and composite materials, modelling and simulation of technological processes of production and assembly of automotive components and their testing.

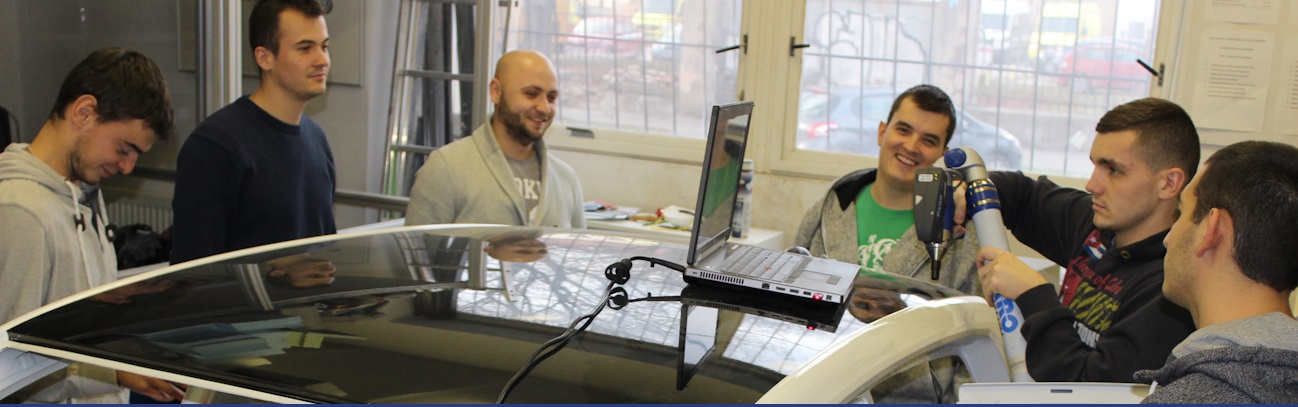

The projects solving focused on the implementation of reverse and simultaneous engineering techniques in the development of automotive components and their testing.

Laboratory of Design and Prototype Manufacturing

Person in charge: Ing. Štefan Kender, PhD.

Location: Mäsiarska 74, ground floor

The laboratory is focused on product design development using state-of-the-art equipment and enables the manufacturing of components from composite materials using modern technologies and processes. Currently, the laboratory is equipped with devices used for scientific and research activities in both basic and applied research, as well as for the preparation of bachelor’s, master’s, and doctoral theses at the department. These include: a testing rig for testing automotive components; a FARO Platinum Arm 3D measuring arm with a laser scanning head and PolyWorks Inspector software; a Microscribe touch 3D scanner; workstations for CAD and computer-aided innovation in product design equipped with software such as Autodesk Maya, Rhinoceros, and Adobe Creative Suite; vacuum technology equipment for manufacturing components from composite materials; an ARGUS 3D optical system inspection microscope; a high-performance workstation for result analysis; and a 3-axis Kompas F 3000 milling/engraving machine, primarily suitable for milling plastics, wood, and plywood, and occasionally aluminum and brass.

|

|

|

|

Laboratory of Automotive Testing and Diagnostics

Person in charge: Doc. Ing. Michal Fabian, PhD.

Location: Mäsiarska 74, ground floor

The laboratory is focused on practical demonstrations of automotive diagnostics and testing. It is equipped with test benches and measuring devices for automotive components. The laboratory also includes vehicles of various manufacturers, such as Škoda, Kia, and Peugeot, which are used as demonstration models during teaching activities. In addition, the laboratory is equipped with measuring devices for diagnosing the functional characteristics and parameters of vehicles. Students have the opportunity to become familiar with their operation and the principles of diagnostics directly during practical demonstrations and exercises. The measured values are subsequently evaluated, and in cases where data indicating various faults or deviations from nominal values are detected, students investigate the causes of their occurrence and observe the consequences of their effects.

|

|

|

|

|

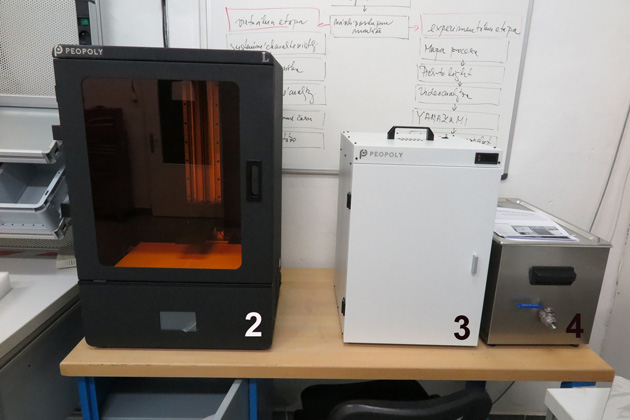

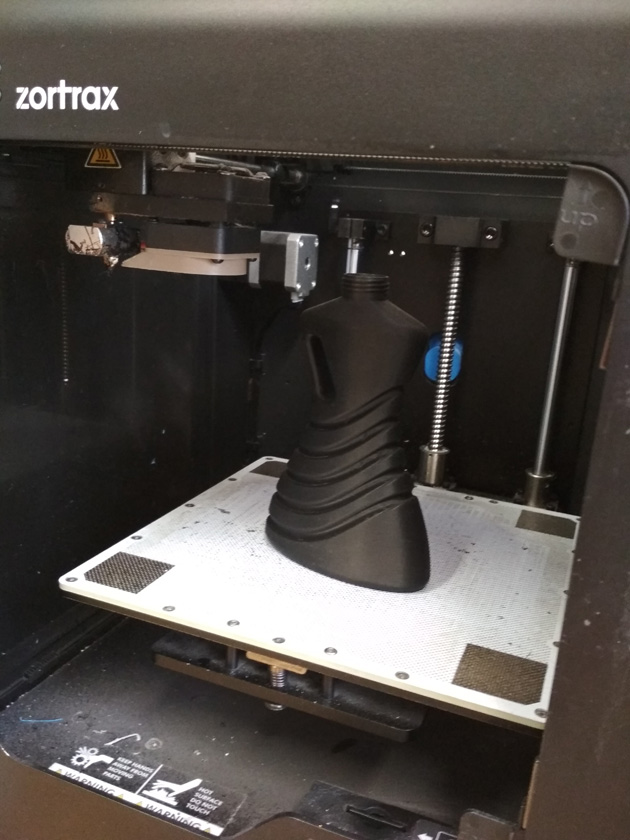

LEANLAB Laboratory and Additive Technologies

Person in charge: Ing. Albert Mareš, PhD., Doc. Ing. Dušan Sabadka, PhD.

Location: Mäsiarska 74, ground floor

TThis laboratory is intended for addressing issues related to manual assembly of products or assembly sub-units of low to medium complexity, using methods and tools of lean manufacturing. The concept makes it possible to connect so-called virtual design with the realization of assembly in the laboratory, to integrate the application of lean assembly methods, to allow the individual application of each method based on specific requirements, and to compare the results of the virtual and experimental parts. A thorough analysis of the product and the manufacturing process using various tools enables the monitoring of assembly operations and the collection of a large amount of data, on the basis of which it is possible to identify value-adding elements (operations or movements), supporting non–value-adding elements, and unnecessary elements that represent waste. Subsequently, training in lean methods can begin, such as 5S (workplace or production process organization), Poka-yoke & Jidoka, Just in Time, bottleneck analysis, KAIZEN events, training in the improvement of standardized work and the implementation of improvement measures, and SMED (e.g., through the design of fixtures, rearranging operations, etc.). Among the most frequently used tools in training are the A3 report, Yamazumi chart, Ishikawa diagram, and others.

For additive technologies, the laboratory is equipped with the following devices:

|

- |

ZORTRAX M200 – single-nozzle, single-material printer; Printing technology: LPD (Layer Plastic Deposition); Build volume: 200 × 200 × 180 mm; Material – filaments: ABS, PLA, Glass, PETG, PCABS, | |

| - | Ultimaker 3 Extended – dual-nozzle, dual-material printer; Printing technology: LPD (Layer Plastic Deposition); Build volume: 197 × 215 × 300 mm; Material – filaments: ABS, PLA, Nylon, PVA, | |

| - | Peopoly Phenom L – printing technology based on photosensitive resins using MSLA (LCD + LED); Printing technology: MSLA (Masked Stereolithography Apparatus); Build volume: 345 × 194 × 400 mm; Material – resins: Deft Resin by Peopoly. |

|

|

|

|

|

|

CAx Technologies Laboratory

Person in charge: Doc. Ing. Miroslav Tomáš, PhD., Doc. Ing. Michal Fabian, PhD.

Location: Mäsiarska 74, ground floor

The laboratory is intended for teaching CAx software such as CATIA, SolidWorks, Autodesk Inventor, PAM-Stamp, and others.

Laboratory of Reverse and Digital Engineering

Person in charge: Ing. Ema Nováková-Marcinčínová, PhD., Ing. Štefan Kender, PhD.

Location: Mäsiarska 74, ground floor

The laboratory is equipped with a FARO touch scanner complemented by a laser scanning head for reverse engineering, as well as HP Reverb G2 virtual reality goggles and Microsoft HoloLens 2 augmented reality goggles.

|

|

|

|

Contact

prof. Janette Brezinová, PhD.

Head of the Department of Automotive Production

Phone No.: +421 55 602 3512

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

doc. Ing. Dušan Sabadka, PhD.

Deputy Head of the Department

Phone No.: +421 55 602 3529

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Secretary: Ing. Eva Krupárová

Phone No.: +421 55 602 3502

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Address

Department of Automotive Production

Mäsiarska 74

040 01 Košice

Slovak Republic

MAP AND GPS COORDINATES

48.7255908526967 , 21.25340531611493

Auto