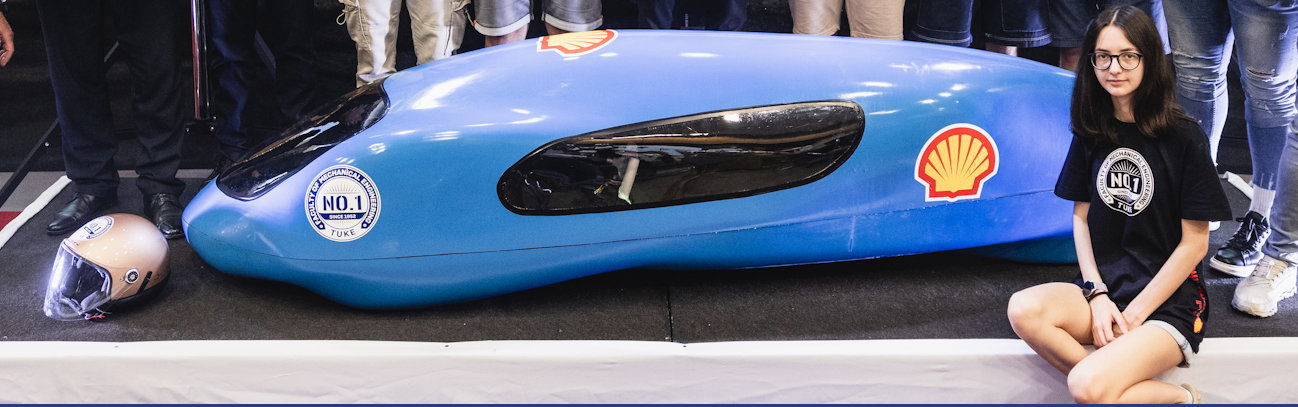

Laboratory of Design and Prototype Manufacturing

Person in charge: Ing. Štefan Kender, PhD.

Location: Mäsiarska 74, ground floor

The laboratory is focused on product design development using state-of-the-art equipment and enables the manufacturing of components from composite materials using modern technologies and processes. Currently, the laboratory is equipped with devices used for scientific and research activities in both basic and applied research, as well as for the preparation of bachelor’s, master’s, and doctoral theses at the department. These include: a testing rig for testing automotive components; a FARO Platinum Arm 3D measuring arm with a laser scanning head and PolyWorks Inspector software; a Microscribe touch 3D scanner; workstations for CAD and computer-aided innovation in product design equipped with software such as Autodesk Maya, Rhinoceros, and Adobe Creative Suite; vacuum technology equipment for manufacturing components from composite materials; an ARGUS 3D optical system inspection microscope; a high-performance workstation for result analysis; and a 3-axis Kompas F 3000 milling/engraving machine, primarily suitable for milling plastics, wood, and plywood, and occasionally aluminum and brass.

|

|

|

|

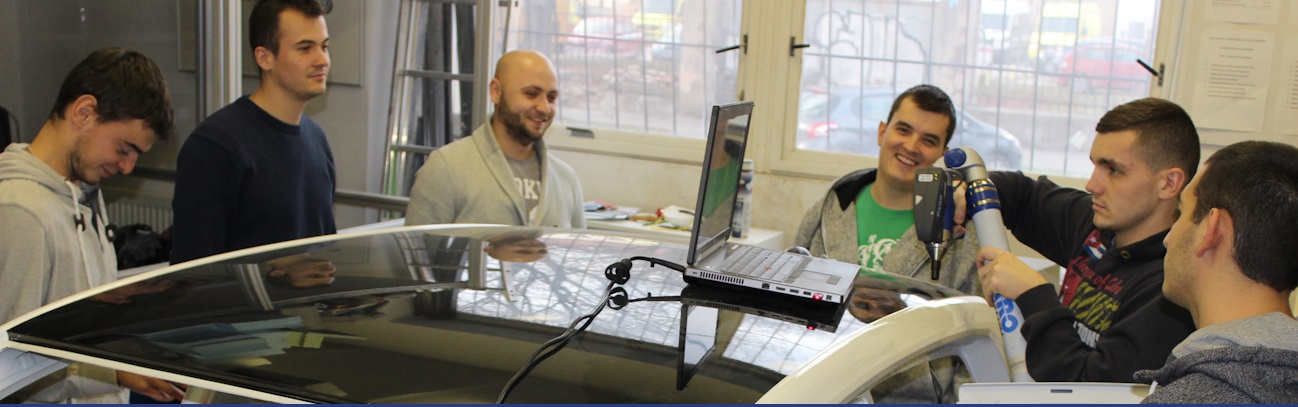

Laboratory of Automotive Testing and Diagnostics

Person in charge: Doc. Ing. Michal Fabian, PhD.

Location: Mäsiarska 74, ground floor

The laboratory is focused on practical demonstrations of automotive diagnostics and testing. It is equipped with test benches and measuring devices for automotive components. The laboratory also includes vehicles of various manufacturers, such as Škoda, Kia, and Peugeot, which are used as demonstration models during teaching activities. In addition, the laboratory is equipped with measuring devices for diagnosing the functional characteristics and parameters of vehicles. Students have the opportunity to become familiar with their operation and the principles of diagnostics directly during practical demonstrations and exercises. The measured values are subsequently evaluated, and in cases where data indicating various faults or deviations from nominal values are detected, students investigate the causes of their occurrence and observe the consequences of their effects.

|

|

|

|

|

LEANLAB Laboratory and Additive Technologies

Person in charge: Ing. Albert Mareš, PhD., Doc. Ing. Dušan Sabadka, PhD.

Location: Mäsiarska 74, ground floor

TThis laboratory is intended for addressing issues related to manual assembly of products or assembly sub-units of low to medium complexity, using methods and tools of lean manufacturing. The concept makes it possible to connect so-called virtual design with the realization of assembly in the laboratory, to integrate the application of lean assembly methods, to allow the individual application of each method based on specific requirements, and to compare the results of the virtual and experimental parts. A thorough analysis of the product and the manufacturing process using various tools enables the monitoring of assembly operations and the collection of a large amount of data, on the basis of which it is possible to identify value-adding elements (operations or movements), supporting non–value-adding elements, and unnecessary elements that represent waste. Subsequently, training in lean methods can begin, such as 5S (workplace or production process organization), Poka-yoke & Jidoka, Just in Time, bottleneck analysis, KAIZEN events, training in the improvement of standardized work and the implementation of improvement measures, and SMED (e.g., through the design of fixtures, rearranging operations, etc.). Among the most frequently used tools in training are the A3 report, Yamazumi chart, Ishikawa diagram, and others.

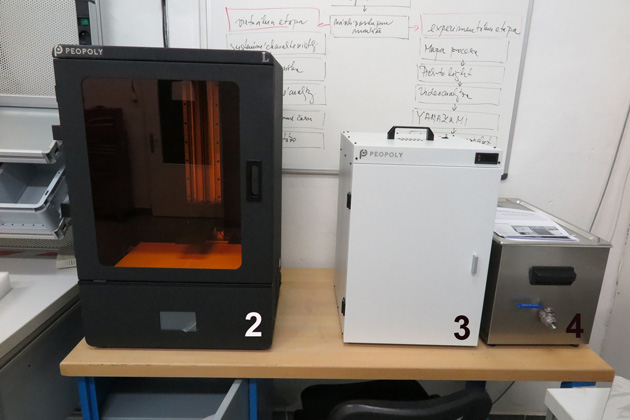

For additive technologies, the laboratory is equipped with the following devices:

|

- |

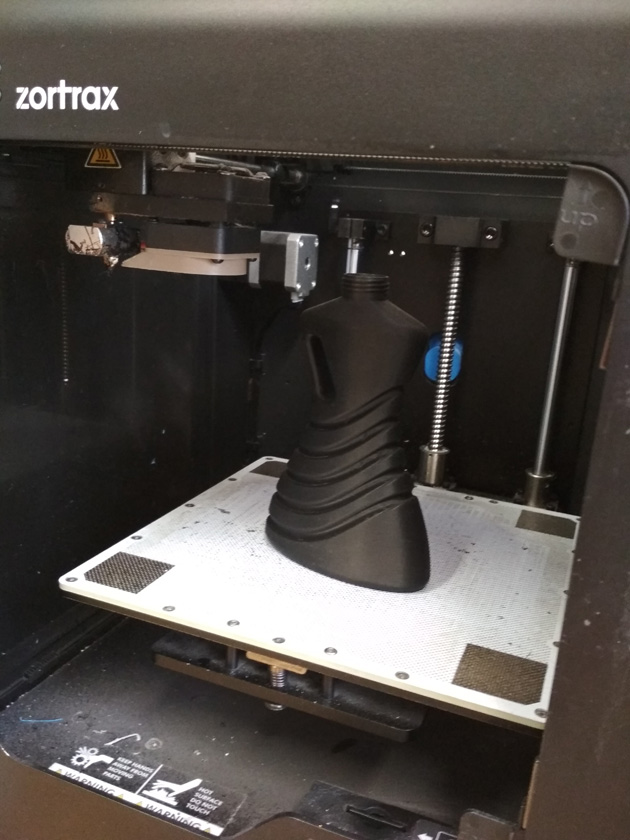

ZORTRAX M200 – single-nozzle, single-material printer; Printing technology: LPD (Layer Plastic Deposition); Build volume: 200 × 200 × 180 mm; Material – filaments: ABS, PLA, Glass, PETG, PCABS, | |

| - | Ultimaker 3 Extended – dual-nozzle, dual-material printer; Printing technology: LPD (Layer Plastic Deposition); Build volume: 197 × 215 × 300 mm; Material – filaments: ABS, PLA, Nylon, PVA, | |

| - | Peopoly Phenom L – printing technology based on photosensitive resins using MSLA (LCD + LED); Printing technology: MSLA (Masked Stereolithography Apparatus); Build volume: 345 × 194 × 400 mm; Material – resins: Deft Resin by Peopoly. |

|

|

|

|

|

|

CAx Technologies Laboratory

Person in charge: Doc. Ing. Miroslav Tomáš, PhD., Doc. Ing. Michal Fabian, PhD.

Location: Mäsiarska 74, ground floor

The laboratory is intended for teaching CAx software such as CATIA, SolidWorks, Autodesk Inventor, PAM-Stamp, and others.

Laboratory of Reverse and Digital Engineering

Person in charge: Ing. Ema Nováková-Marcinčínová, PhD., Ing. Štefan Kender, PhD.

Location: Mäsiarska 74, ground floor

The laboratory is equipped with a FARO touch scanner complemented by a laser scanning head for reverse engineering, as well as HP Reverb G2 virtual reality goggles and Microsoft HoloLens 2 augmented reality goggles.

|

|

|

|

Contact

prof. Janette Brezinová, PhD.

Head of the Department of Automotive Production

Phone No.: +421 55 602 3512

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

doc. Ing. Dušan Sabadka, PhD.

Deputy Head of the Department

Phone No.: +421 55 602 3529

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Secretary: Ing. Eva Krupárová

Phone No.: +421 55 602 3502

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Address

Department of Automotive Production

Mäsiarska 74

040 01 Košice

Slovak Republic

MAP AND GPS COORDINATES

48.7255908526967 , 21.25340531611493

Auto