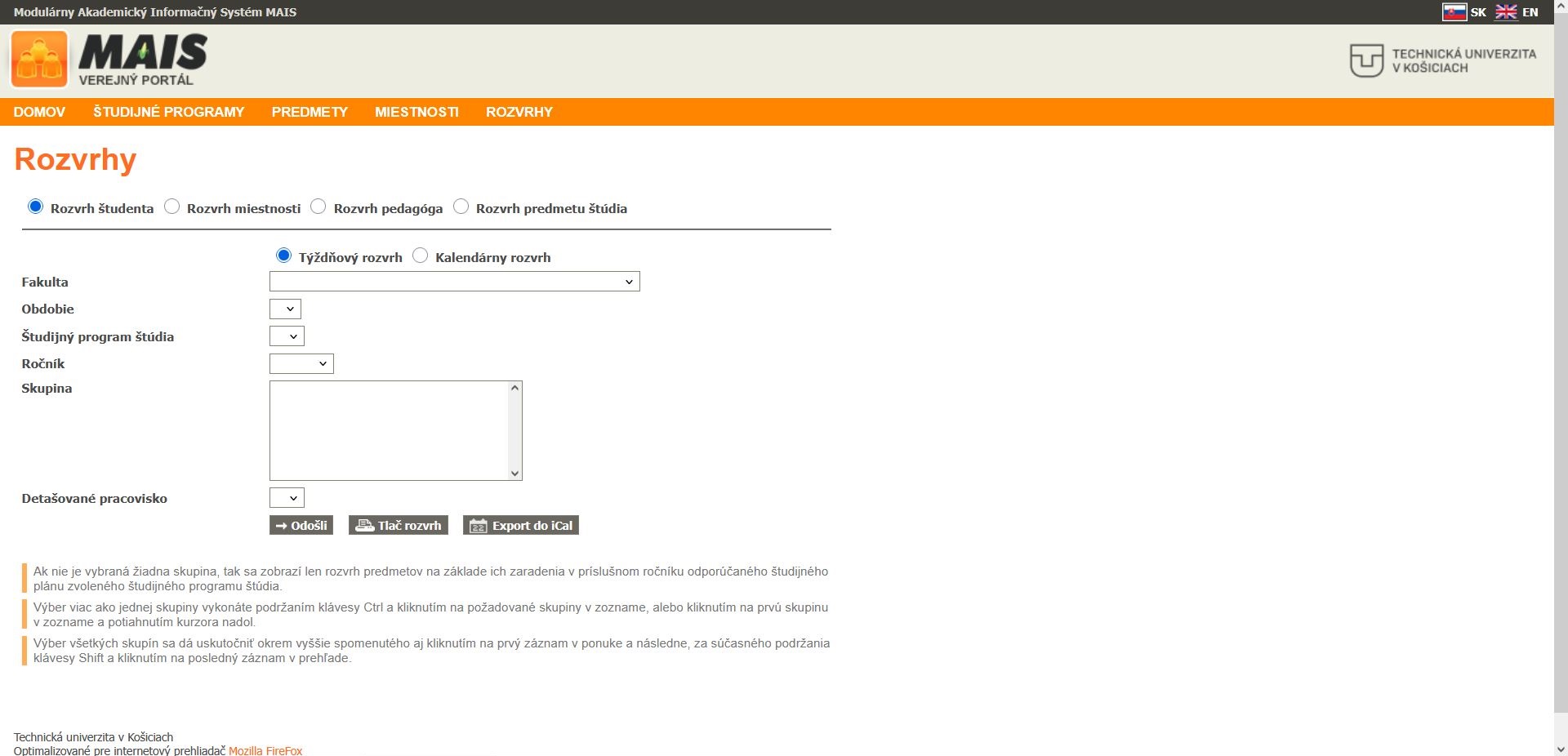

Aktuálne rozvrhy nájdete na: https://maisportal.tuke.sk/portal/rozvrhy.mais

BAKALÁRSKY ŠTUDIJNÝ PROGRAM

Automobilová výroba (AV)

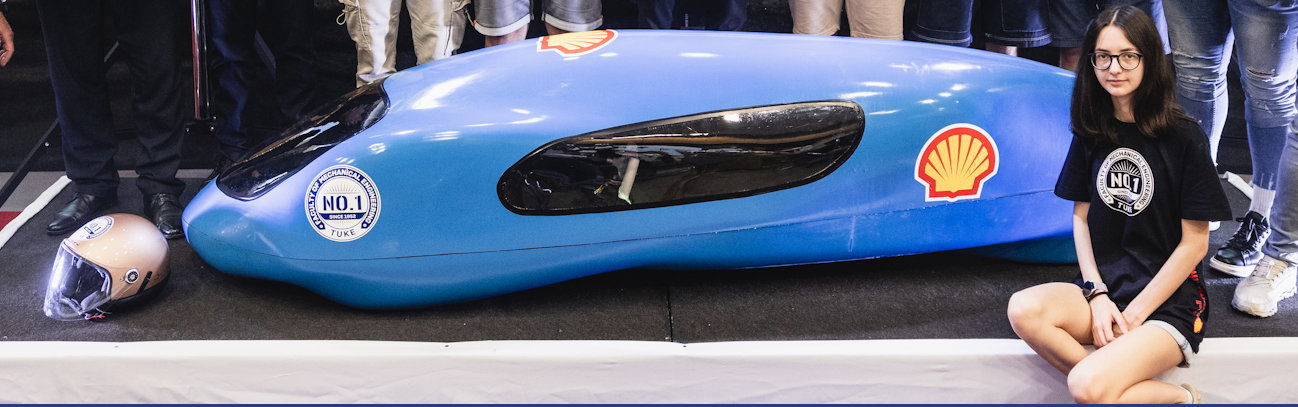

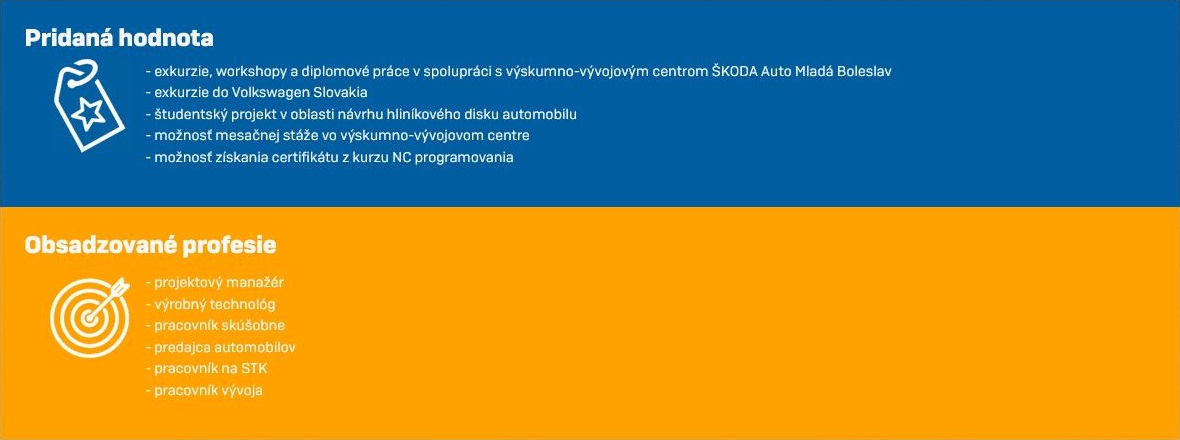

Výchova a vzdelávanie poslucháčov bakalárskeho štúdia študijného programu Automobilová výroba je zameraná na získanie teoretických vedomosti a praktických skúseností z oblasti progresívnych materiálov, technológií, analytických nástrojov pri navrhovaní komponentov automobilov, organizácii ich výroby a ich montáži s podporou CAx technológií. Študenti si môžu ďalej rozvíjať svoje kreatívne a inovatívne zručnosti pri riešení prípadových štúdií, projektov ECO Sheel Marathon a úprav elektromobilu Volkswagen e-up! Súčasťou profilu absolventa sú aj znalosti a zručnosti z oblasti skúšania, predaja automobilov, riadenia prevádzky, riadenia údržby automobilov a iných činností súvisiacich s automotive v súlade so požiadavkami štandardov kvality ISO TS 16949. Absolventi získajú skúseností z tímovej práce pri riešení technických problémov, riadenia malých tímov a zdokonalenie sa v prezentačných a komunikačných zručnostiach. Študijný program Automobilová výroba umožní absolventom vstúpiť do sveta výroby automobilov, riadenia predaja, servisu, STK automobilov a dodávateľského sektora automobilového priemyslu.

Hlavné oblasti zamerania

Stupne a formy štúdia

Denná forma štúdia - SK - štúdium v slovenskom jazyku , EN - štúdium v anglickom jazyku

|

Podmienky prijatia na bakalársky študijný program |  |

Podať prihlášku |

INŽINIERSKY ŠTUDIJNÝ PROGRAM

Automobilová výroba (AV)

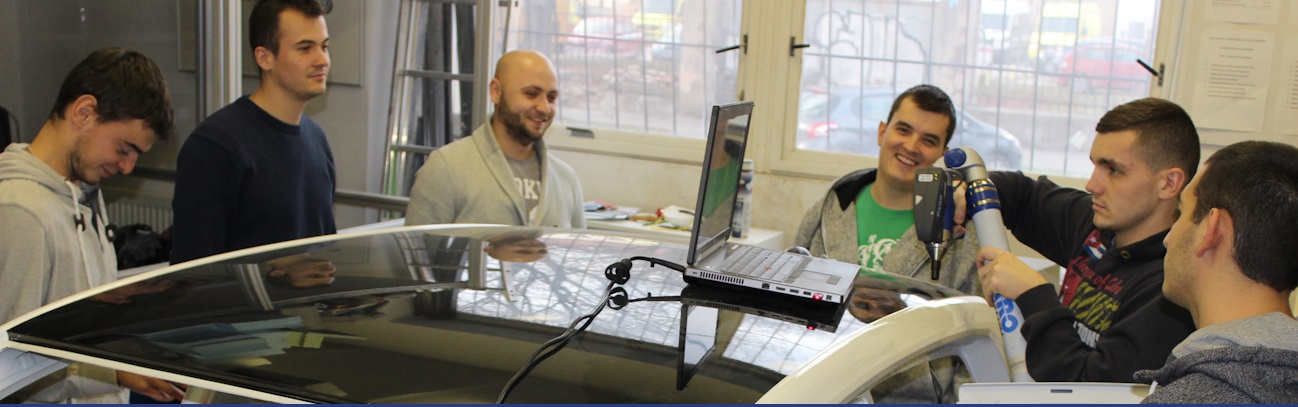

Výchova a vzdelávanie poslucháčov študijného programu Automobilová výroba je zameraná na prípravu odborníkov pre tvorbu nových výrobkov, projektovanie výrobných procesov, riadenie výroby automobilov a ich komponentov. Absolventi získajú teoretické, výskumné, odborné i praktické poznatky o inovačných trendoch v automobilovej výrobe. Získajú znalosti a spôsobilosti z oblastí: technológií výroby komponentov automobilov, montáže automobilov, testovania, výrobnej techniky, štruktúry výrobných pracovísk, logistiky a organizácie dodávateľských reťazcov v automobilovom priemysle. Absolventi získavajú znalosti o tvorbe nových a inovovaných výrobkov technikami počítačom podporovaného dizajnu a konštruovania, virtuálnej reality, tvorby prototypov ale aj v oblasti reverzného inžinierstva. Ovládajú metódy štíhlej a agilnej výroby. Súčasťou profilu absolventa je aj znalosť cudzieho jazyka a primerané vedomosti z ekonomiky, manažmentu, environmentalistiky a bezpečnosti. Absolventi majú ďalšie znalosti, na báze ktorých sú schopní pracovať v tíme s ostatnými profesiami participujúcimi na zabezpečení výroby (marketingu, servisných služieb, logistiky, atď.).

Hlavné oblasti zamerania

Stupne a formy štúdia

Denná forma štúdia - SK - štúdium v slovenskom jazyku , EN - štúdium v anglickom jazyku

|

Podmienky prijatia na inžiniersky študijný program |  |

Podať prihlášku |

Consultation hours for WS 2025 - updated on 30.09.2025

ERASMUS is a pan-European mobility program that provides students at all three levels of higher education with the opportunity to complete a study stay at European universities as well as practical internships in foreign companies or organizations.

Basic, general information about the ERASMUS programme can be found at: https://erasmus.tuke.sk/en/

and specific detailed information for those interested in student mobility for the purpose of study and for the purpose of practical internship can be found at: https://erasmus.tuke.sk/calls-for-mobility-students/

Forms:

Application to travel for foreign mobility

List of Subjects for Recognition

Faculty coordinator of Eramus+ and Ulysseus

Assoc. Prof. Ing. Ivan Gajdoš, PhD.

Consultation hours:

Friday: 9:00 – 10:00

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Address:

Office No.: 104, Mäsiarska 74, 040 01 Košice - old town

Phone No.: +421 55 602 3518

Začiatok akademického roku: 01.09.2025

Slávnostné otvorenie AR 2025/2026: 22.09.2025 o 11:00 hod. v Aule Maxima

Koniec akademického roku: 31.08.2026

Zápis na štúdium

1. ročník Bc. a Ing. štúdium, e-zápis v systéme MAIS: 01.07.2025 – 06.07.2025

Postupové ročníky, e-zápis na štúdium v systéme MAIS: 03.09.2025 – 07.09.2025

Imatrikulácia: 06.11.2025

Zápis predmetov na AR 2025/2026

1. kolo - zápis predmetov v systéme MAIS: 23.06.2025 – 06.07.2025

Zimný semester

Výučba: 22.09.2025 – 19.12.2025

Zimné prázdniny: 22.12.2025 – 02.01.2025

Skúškové obdobie: 05.01.2026 – 13.02.2026

Uzávierka ZS v IS MAIS: 18.02.2026 (ukončenie hodnotenia za ZS AR 2025/2026)

Letný semester

Výučba - postupové ročníky: 16.02.2026 – 15.05.2026

Výučba - končiace ročníky: 16.02.2026 – 24.04.2026

Skúškové obdobie: 18. 05. 2026 – 30.06.2026

Letné prázdniny: 01.07.2026 – 31.08.2026

Uzávierka LS v IS MAIS: 03.07.2026 (ukončenie hodnotenia za AR 2025/2026)

Záver štúdia

Uzávierka absolvovaných predmetov pre končiace ročníky: 22.05.2026

Odovzdanie bakalárskych a diplomových prác: do 07.05.2026

Štátne skúšky a obhajoby bakalárskych a diplomových prác: 01.06.2026 – 12.06.2026

Nácvik na promócie inžinierov: 25.06.2026

Promócie inžinierov: 30.06.2026

Odovzdávanie Bc. diplomov: 02.07.2026

Štátne sviatky:

Zimný semester:

17.11.2025 – pondelok

Letný semester:

03.04.2026 – piatok

06.04.2026 – pondelok

01.05.2026 – piatok (dňa 30.04.2026 (štvrtok) – výučba ako v piatok)

08.05.2026 – piatok (dňa 06.05.2026 (streda) – výučba ako v piatok)

Conference about Industry 4.0 in the automotive industry

Within the grant project no. 21640389 supported by the Visegrad fund (www.visegradfund.org), the Department of automobile production cooperate on preparation of the conference "INDUSTRY 4.0 in the Automotive Industry: how to adapt university education to new challenges in industry." The scheduled date for the conference is October 2017.

The project partners are:

The automotive industry has great importance for the Central European region. At present, the automotive industry is increasingly determined by the trend referred as INDUSTRY 4.0. In addition, this trend is a challenge for the automotive industry, and it is also a challenge faced by universities. INDUSTRY 4.0 is itself a very complex topic of education and therefore cooperation between universities is inevitable.

The main goal of the project is to gather and share knowledge and experience about current praxis in INDUSTRY 4.0. Another goal is development of education module for Industry 4.0 for the participating universities, so that new graduates can start their career in the automotive industry with experience in Industry 4.0.

Contact

prof. Janette Brezinová, PhD.

Head of the Department of Automotive Production

Tel.: +421 55 602 3512

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

doc. Ing. Dušan Sabadka, PhD.

Deputy Head of the Department

Tel.: +421 55 602 3529

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Secretary: Ing. Eva Krupárová

Tel.: +421 55 602 3502

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Address

Department of Automotive Production

Mäsiarska 74

040 01 Košice

Slovak Republic

MAP AND GPS COORDINATES

48.7255908526967 , 21.25340531611493

Auto