Laboratory of tribology (M74-041/A)

Responsible persons: prof. Ing. Ján Slota, PhD., Ing. Gerhard Mitaľ, PhD.

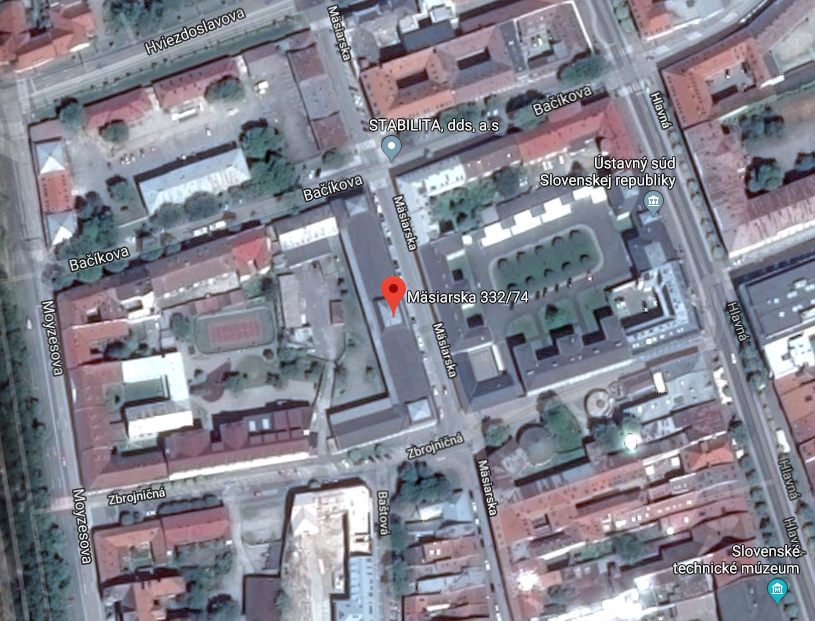

Location: Mäsiarska 74

Focus of laboratory

Research in the field of tribological properties of materials and their surfaces. Tests of resistance to various types of wear of metallic and non-metallic materials, tests of microhardness of surfaces and surface layers, as well as research on biomaterials used for joint replacements in the human body. Due to the interdisciplinary nature of tribology, PC systems are applied in the laboratory in the creation of programs for the management and control of tribological test parameters. At present, the laboratory houses equipment that is used for scientific and research activities of basic and applied research, as well as for the solution of final bachelor, diploma and doctoral theses in the department.

Laboratory equipment

- Leica microscopes type ICC50W and stereomicroscope S9i from the manufacturer Leica Microsystems.

- Stereomicroscope NIKON SMZ 1500 made by Nikon.

- Certified digital scales, manufacturer KERN, with a load capacity of up to 2.5 kg and an accuracy of 0.0001 g.

- Metallographic microscope Neophot 21, manufacturer Carl Zeiss.

- Alfred Amsler 135/309 from WOLPERT WERKSTOFFPRUFMASCHINEN, Switzerland, designed for adhesive wear resistance tests, allowing testing of sliding pairs in different test conditions with or without lubricant, which includes MATLAB Simulink software.

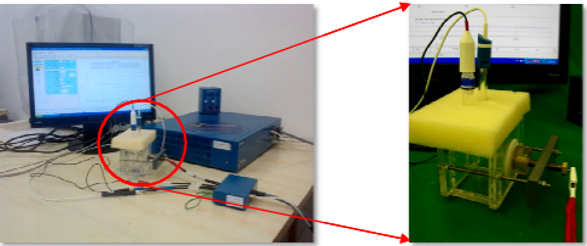

- The ELTC tribometer on which the biomaterials research is carried out is PC controlled. It is also used for special tribological tests (Utility Model No. 6580), which models sliding reciprocating motion conditions even at elevated temperature with lubrication thus meeting the demanding requirements for testing.

Blasting and Coating Laboratory (M74-A_139)

Responsible person: doc. Ing. Dagmar Draganovská, PhD.

Location: Mäsiarska 74

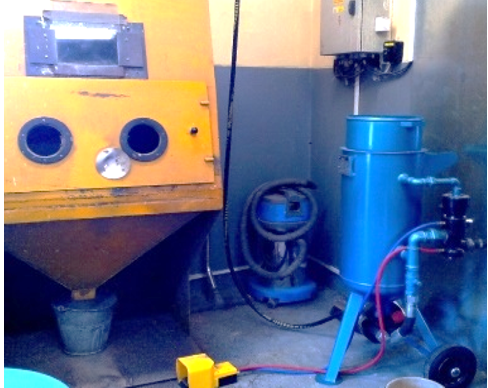

Focus of the laboratory

The laboratory focuses on research in the field of surface pretreatment by blasting and on the assessment of abrasive wear of materials. The laboratory contains equipment used for scientific and research activities in basic and applied research, as well as for the solution of final bachelor, master and doctoral theses in the department. The professional focus of the laboratory: creation of blasted surfaces by different types of blasting agents in terms of material base - metallic or non-metallic as well as in terms of shape - sharp-edged or spherical blasting agent, evaluation of abrasive wear of abrasion-resistant materials, coatings and coatings, determination of stress ratios of materials after blasting by Almen test, evaluation of the roughening effect of blasting agents, evaluation of the abrasion-resistant properties of functional coatings.

Laboratory equipment

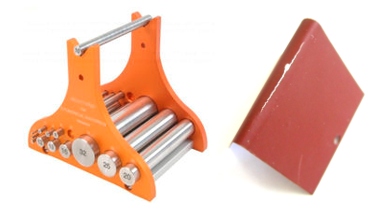

pneumatic blasting equipment, type TJVP - 320 and Di - 1 equipment for the evaluation of abrasive wear of abrasion resistant materials, coatings and coatings

Other equipment of the laboratory is the possibility of applying powder coatings in an electrostatic field, the application of organic coatings by spraying and the Airless Spraying Machine - Wagner W400SE.

Welding and Defectoscopy Laboratory (M74-036)

Responsible person: prof. Ing. Ján Viňáš, PhD., IWE, EWE

Location: Mäsiarska 74

Focus of the laboratory

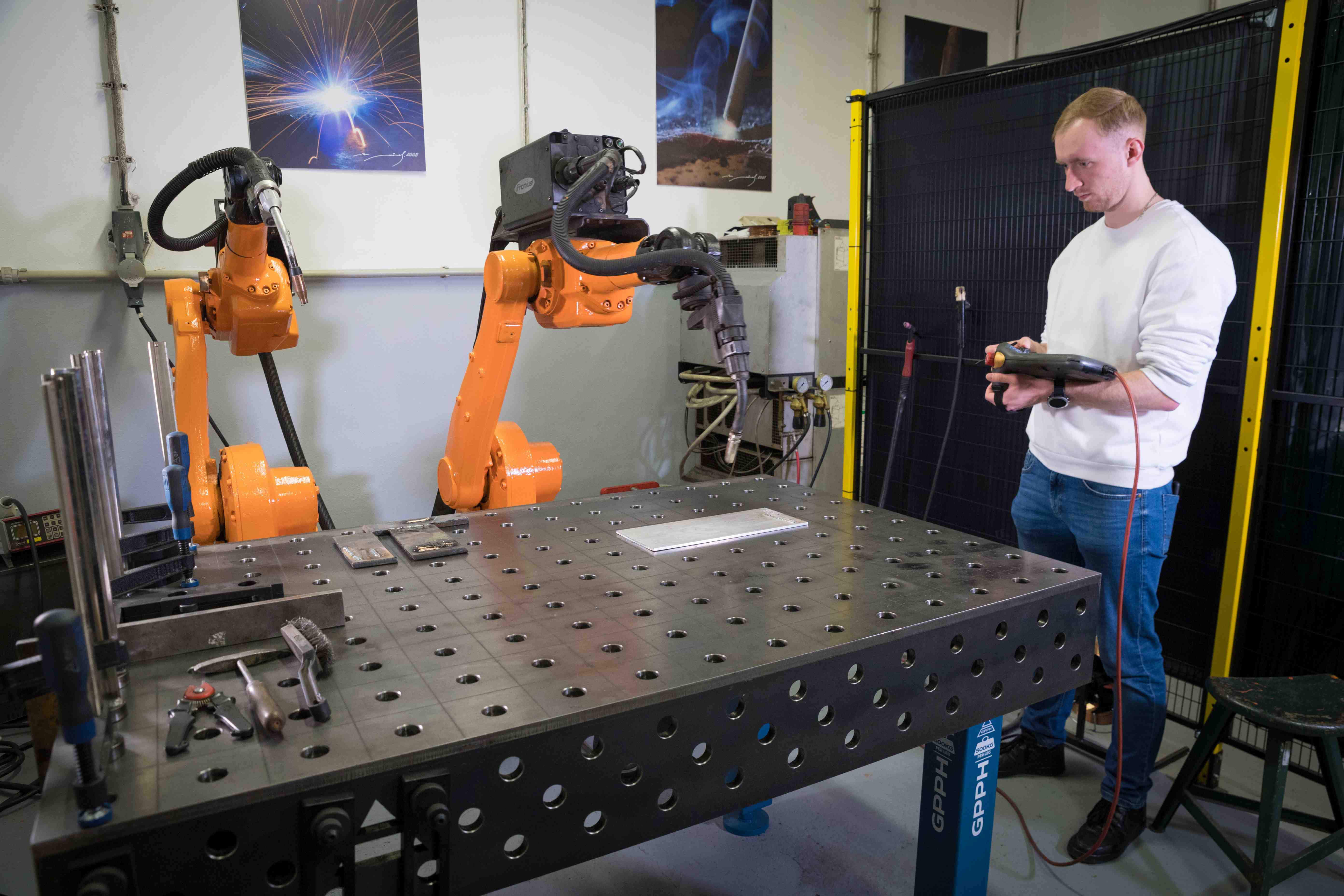

The laboratory focuses on the research of cutting, soldering, welding, welding of materials as well as the evaluation of the quality of welded joints. It is aimed at gaining practical experience in flame welding, manual arc welding, MIG/MAG/TIG welding and resistance welding. The laboratory is also designed as a training facility (Welding School) for manual arc welding in accordance with STN 05 0600 and STN 05 0630, consisting of four teaching boxes and one instructor's station. At present, the laboratory contains equipment used for scientific and research activities of basic and applied research, as well as for the solution of final bachelor, diploma and dissertation theses in the department. The laboratory is used for teaching non-destructive methods of weld testing. NDT quality control of welded joints is carried out by means of visual and capillary testing. The professional focus of the laboratory is the optimization of welding processes and the investigation of the quality of welded joints.

Laboratory equipment

Welding equipment Fronius MagicWave 4000 Job, WTU 600, KSM 100, EssetyMiny, Formica 169, CLOOS MC 303 and pneumatic spot welder VTS BPK 20. The laboratory also includes a tandem robotic welding workplace equipped with two ABB IRB 1600 robots in interaction with Fronius TransSynergic 4000 and SKS welding machines, enabling welding with MIG/MAG methods as well as with the progressive CMT (Cold metal transfer) method.

Surface evaluation and surface treatment laboratory (M74-A_LPÚ)

Responsible person: doc. Ing. Dagmar Draganovská, PhD.

Location: Mäsiarska 74

Focus of the laboratory

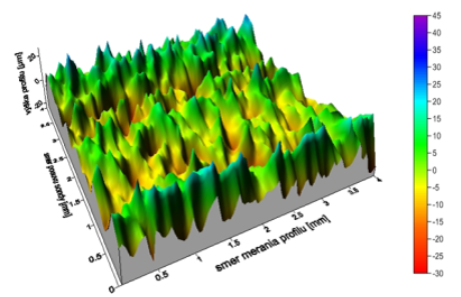

The laboratory focuses on research in the field of surface quality and evaluation of coating properties. Currently, the laboratory houses equipment used for scientific and research activities in basic and applied research, as well as for the solution of final bachelor's, master's and doctoral theses. The professional focus of the laboratory includes diagnosis of metallic and non-metallic surfaces, evaluation of basic substrates and coatings in terms of their morphology, measurement of microgeometry using touch profilometers, testing of coatings, evaluation of surface and coating interaction, measurement of surface activity.

Laboratory equipment

Surftest SJ-301 and SJ-201 contact roughness meters, QuaNix thickness gauge for coating thickness determination, APGi instrument for determination of abrasive wear of coatings, SP-150 potentiostat for electrochemical impedance spectroscopy, an Elcometer 510 hydraulic tear-off gauge for determining the adhesion of coatings, an Elcometer apparatus for determining the adhesion of coatings by grid test and a cylindrical mandrel apparatus for carrying out bending tests on coatings.

Light microscopy and metallography laboratory (M74-155)

Responsible persons: doc. Ing. Anna Guzanová, PhD., doc. Ing. Ľuboš Kaščák, PhD.

Location: Mäsiarska 74, 1 floor

Focus of the laboratory

The laboratory focuses on metallographic study and documentation of macro and microstructures of metallic and non-metallic materials, layers and coatings, determination of corrosion characteristics of base materials, evaluation of corrosion efficiency of layers and coatings, measurement of microhardness of materials, analysis of fracture surfaces and topography of surfaces. The laboratory also houses equipment used for scientific and research activities in basic and applied research, as well as for the solution of final bachelor's, master's and doctoral theses.

Laboratory equipment

Metallographic grinder and polisher Struers Tegramin - 20, chemical digester ALK 697, ultrasonic cleaner, mechanical grinder - polisher Buehler, condensing chamber Liebisch Constanzo KBEA 300, condensing chamber KK 320, digital microscope Keyence VHX - 5000, Neophot-2 light microscope, Olympus BXFM metallographic microscope, Carl Zeiss Epityp 2 microscope, BK 70x50 microscope, Belec Compact Port mobile spectrometer, BioLogic SP-150 device for measuring electrochemical characteristics of surfaces, Aqualab water distiller, Witeg MSH-D magnetic liquid stirrer with heating, See System apparatus for measuring the surface energy of solids by determining the contact angle of the drop, Mettler Toledo pH meter, Shimadzu HMV-2 microcurrent meter.

Mäsiarska 74

040 01 Košice - Old town

Slovak Republic

Contact

Department of Technology, Materials and Computer-Aided Technologies

Institute of Technology and Materials Engineering

Faculty of Mechanical Engineering

Technical University of Košice

Head of the department and director of the institute: prof. Ing. Emil Spišák, CSc.

phone: 055/602 3502

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Secretariat: Ing. Eva Krupárová

phone: 055/602 3502

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

https://www.facebook.com/KatPPT