LSP1 Classroom of the production programming on CNC machines (M74-040/A)

Responsible person: Ing. Ján Varga, PhD.

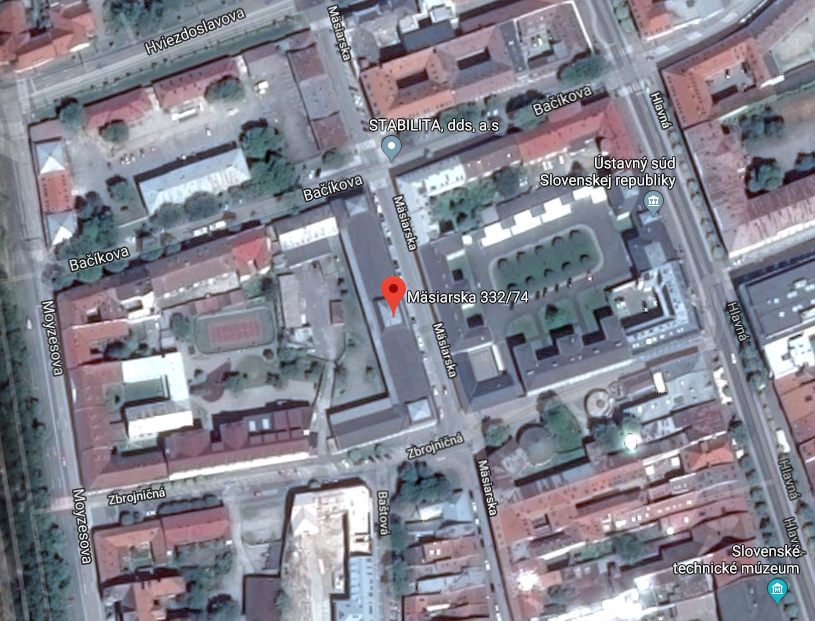

Location: Mäsiarska 74

Focus of the classroom

The CNC machine tool manufacturing programming classroom focuses on CAD part designs, programming methods and toolpath creation for complex part machining. The learning process addresses the proper selection of part manufacturing technology with respect to achieving the required accuracy based on drawing documentation. The classroom is used for educational purposes as well as professional training of students in the study programs of bachelor studies (PPSV, TMaISV), engineering studies (PPSV, ST). Within these disciplines, students acquire skills in working with software tools in the areas of CAD/CAM technologies that are used in engineering practice.

Classroom software equipment

- Solidworks 2021

- SolidCAM 2021

- NX

- Catia

In the classroom of production programming on CNC machine tools there are 10 EMCO programming consoles with panels for Heidenhaim TNC 460 and Sinumerik 840D control systems. The programming consoles are used to understand the essence of the milling and turning process with direct links to the real process through the EMCO concept Mill 155 CNC milling machine and the DMG CTX 310 eco CNC lathe, which are part of the educational process. The classroom is used to gain experience in shop floor programming through the consoles and programming of shaped surfaces through CAM software, which students can use in their term papers, theses, or in the realization of their own designs.

Subjects teaching

- Introduction to NC programming

- CAD/CAM systems in technology

- NC machine programming

Machining Laboratory (M74-040/A)

Responsible person: Ing. Ján Varga, PhD.

Location: Mäsiarska 74

Focus of the laboratory

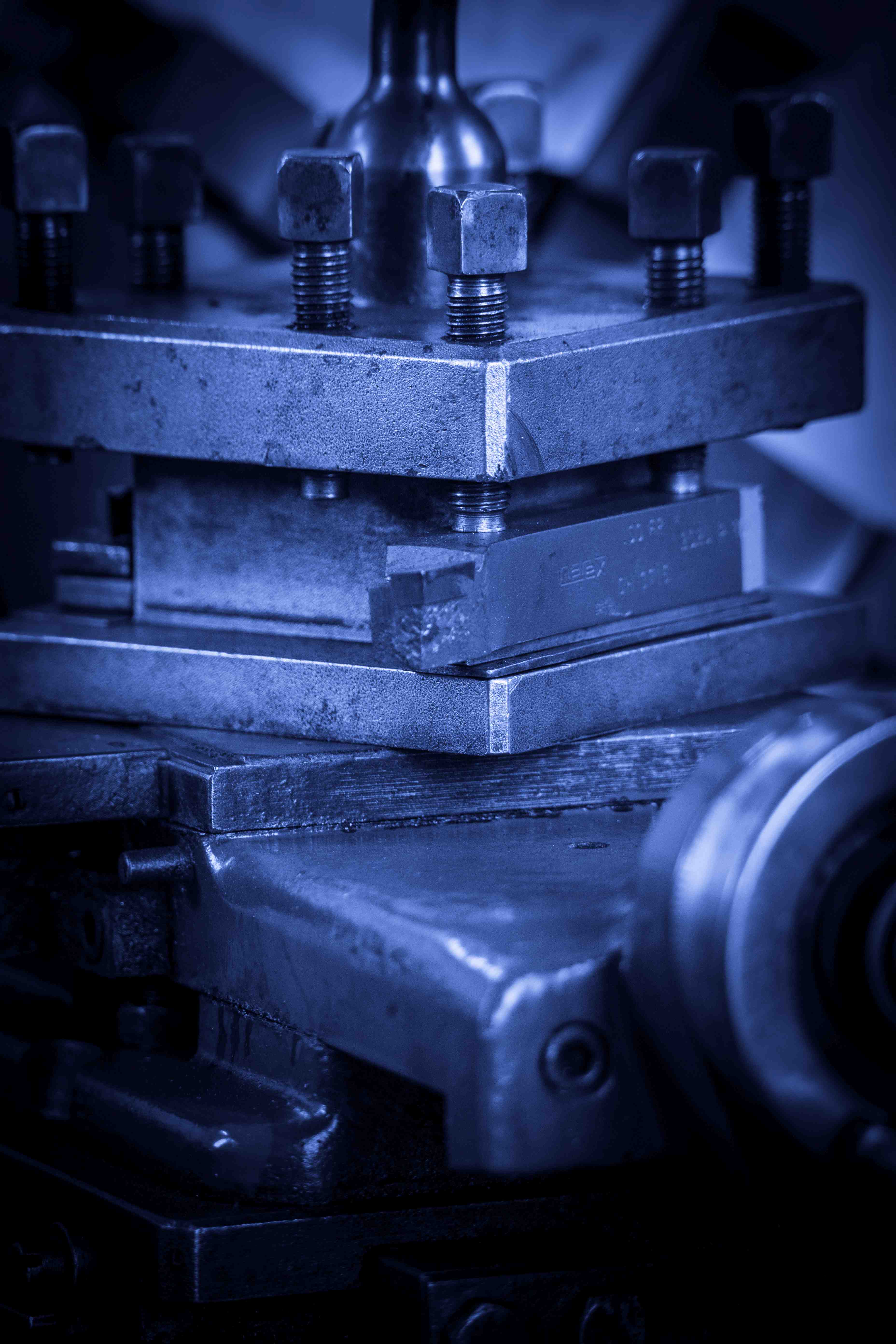

The laboratory focuses on research into the machinability of materials and the cutting performance of tools. Currently, the laboratory houses equipment used for scientific and research activities in basic and applied research, as well as for the solution of final bachelor, master and doctoral theses in the department. The laboratory's areas of expertise include the measurement of cutting force components, monitoring of machining, cutting edge durability, formation and condition of the machined surface, and control of chip formation.

Laboratory equipment

CNC milling machine with control system Heidenhain TNC 640, CNC lathe machine with control system Sinumerik 840D, vertical milling machine FA 2W, universal cylindrical lathe S 28, universal cylindrical lathe S 18 RA, universal cylindrical lathe SUI 50, universal grinder Nl, universal cylindrical grinder SWA 10, plane grinder SPC 20, double disc grinder BAD 20, universal horizontal milling machine FWD 25, universal horizontal milling machine FWC 26, edging machine GH 5603, bench drills V 10A, V 23 A,V 20, machine metal saw MS 160, frame saw 872, bench grinder BM 350, bender 1000/3, bender 1000/3, plate lever shears, machine shears.

M74-038 Rapid prototyping and reverse engineering laboratory

Responsible persons: prof. Ing. Ján Slota, PhD., doc. Ing. Ivan Gajdoš, PhD.

M74-028 Laboratory of production programming on CNC machines

Responsible person: Ing. Ján Varga, PhD.

M74-108 3D optical deformation measurement laboratory

Responsible persons: prof. Ing. Ján Slota, PhD.

M74-026 Plastics Processing laboratory

Responsible persons: doc. Ing. Ľudmila Dulebová, PhD., doc. Ing. Ivan Gajdoš, PhD.

Responsible person: doc. Ing. Janka Majerníková, PhD.

M74-040/A Machining laboratory

Responsible person: Ing. Ján Varga, PhD.

M74-044 Mechanical and Technological testing laboratory

Responsible person: doc. Ing. Ľudmila Dulebová, PhD.

M74-155 Light microscopy and metallography laboratory

Responsible persons: doc. Ing. Anna Guzanová, PhD., doc. Ing. Ľuboš Kaščák, PhD.

M74-036 Welding and Defectoscopy laboratory

Responsible person: prof. Ing. Ján Viňáš, PhD., IWE, EWE

M74-A_LPÚ Surface evaluation and surface treatment laboratory

Responsible person: doc. Ing. Dagmar Draganovská, PhD.

M74-A_139 Blasting and Coating laboratory

Responsible person: doc. Ing. Dagmar Draganovská, PhD.

M74-041/A Laboratory of tribology

Responsible persons: prof. Ing. Ján Slota, PhD., Ing. Gerhard Mitaľ, PhD.

Rapid prototyping and reverse engineering laboratory (M74-038)

Responsible persons: prof. Ing. Ján Slota, PhD., doc. Ing. Ivan Gajdoš, PhD.

Location: Mäsiarska 74

Focus of the laboratory

The laboratory is aimed at gaining practical experience in rapid prototyping. Currently, the laboratory houses equipment that is used for scientific and research activities in basic and applied research, as well as for the solution of final bachelor, master and doctoral theses in the department. The laboratory's expertise is the production of prototypes, measurement of mass changes in materials in order to determine their composition, thermal stability and related phenomena.

Laboratory equipment

3D production equipment FORTUS 400mc for rapid production of prototypes from Polycarbonate and Ultem material, 3D printer DIMENSION SST 3D Printer for rapid production of prototypes from ABS material, workstation (PC) with software for conversion of models into STL file format and their analysis, TGA/DSC thermogravimetric analyzer.

Mäsiarska 74

040 01 Košice - Old town

Slovak Republic

Contact

Department of Technology, Materials and Computer-Aided Technologies

Institute of Technology and Materials Engineering

Faculty of Mechanical Engineering

Technical University of Košice

Head of the department and director of the institute: prof. Ing. Emil Spišák, CSc.

phone: 055/602 3502

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Secretariat: Ing. Eva Krupárová

phone: 055/602 3502

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

https://www.facebook.com/KatPPT