Guarantor of the study program: prof. Ing. Peter DEMEČ, CSc.

Form of study: full-time / part-time

Standard length of study: 4 years / 5 years

PROFILE AND APPLICATION OF GRADUATES OF THE PRODUCTION TECHNOLOGY STUDY PROGRAM

GRADUATE PROFILE

The study is focused on the preparation of highly qualified experts in scientific research, development and practice in all fields and workplaces where scientific knowledge of the construction of production technology is applied.

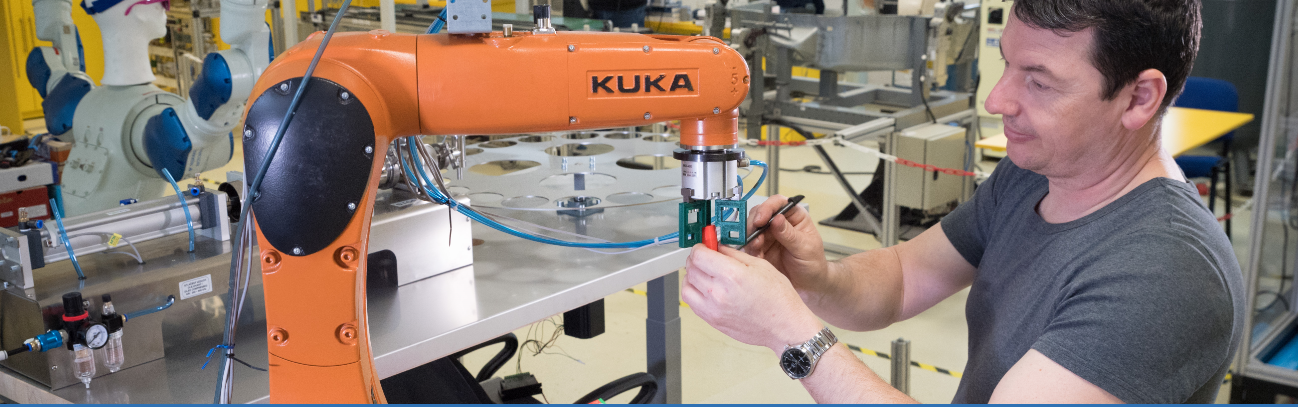

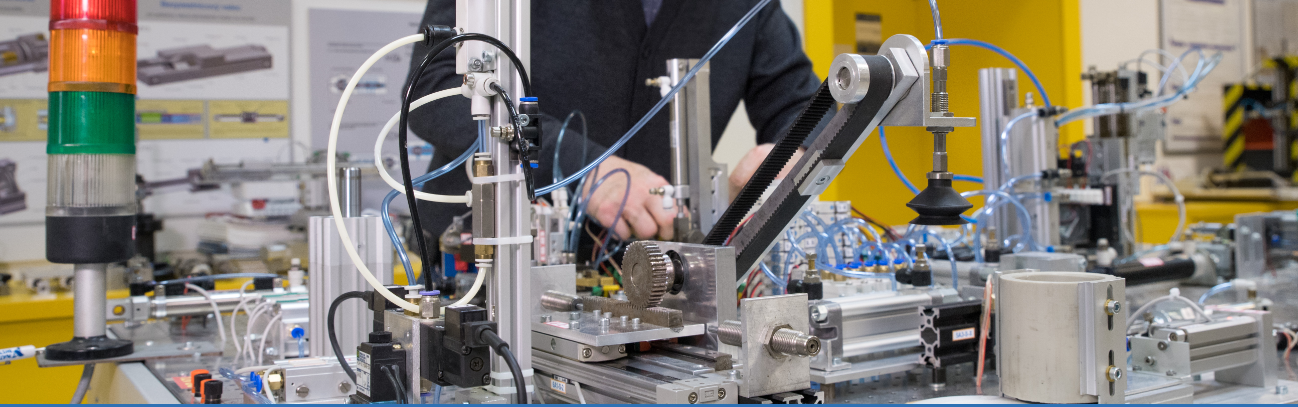

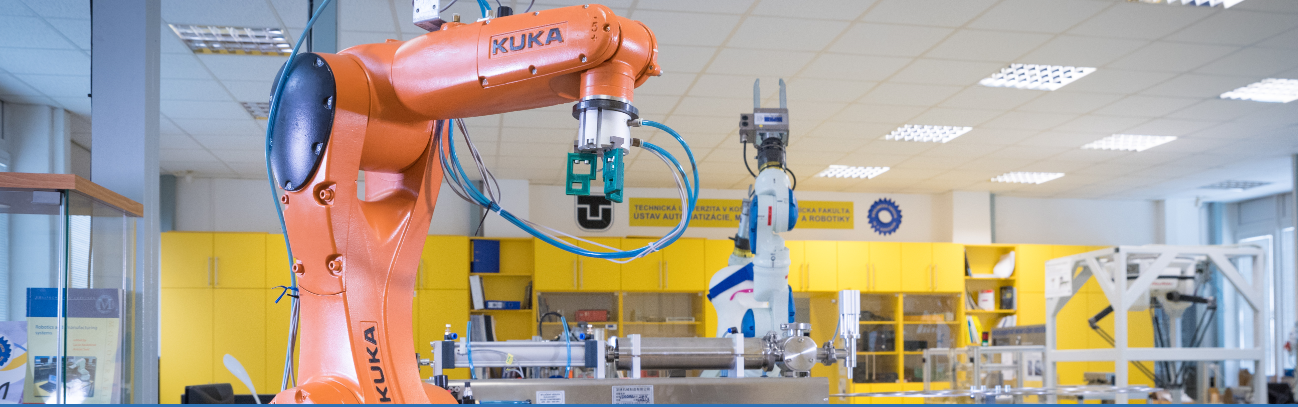

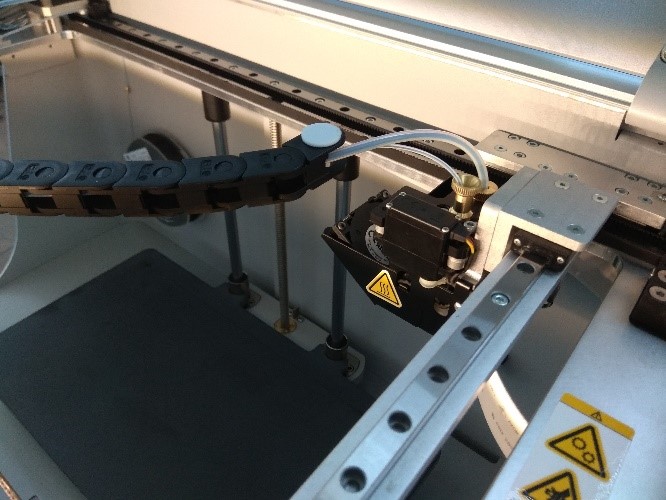

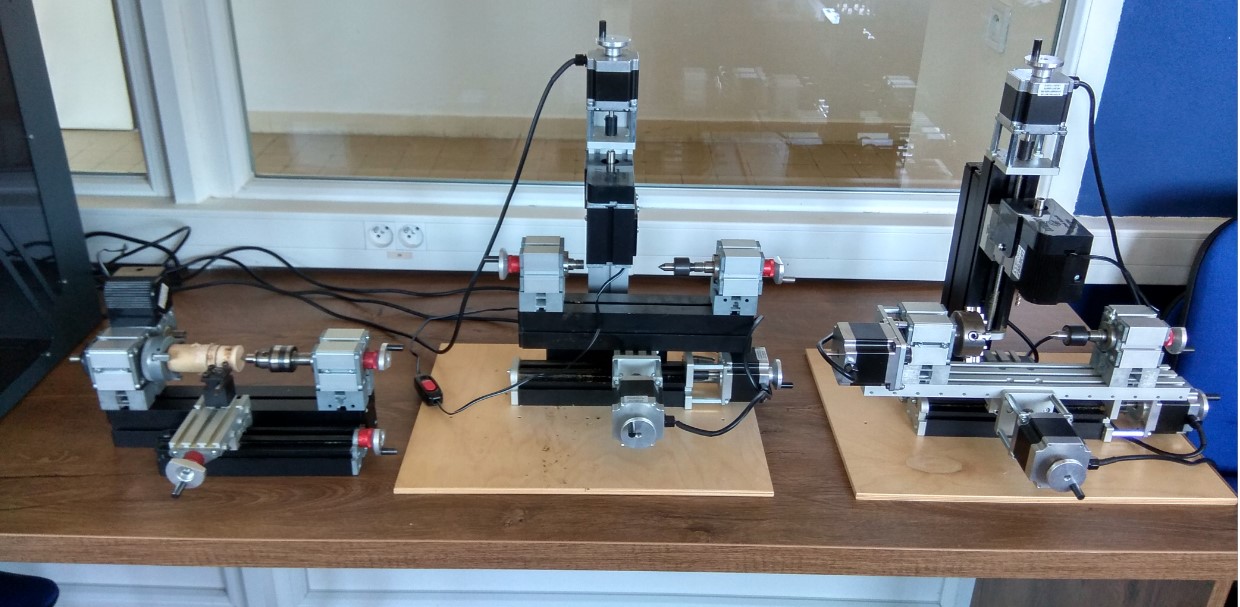

Graduates of the study program Production Technology in the field of study Production Technology masters scientific methods of research and development of production technology with an orientation on the development of machine tools, forming, welding, foundry machines, industrial and service robots, as well as production machines and systems for non-engineering industries.

The graduate of the doctoral study program Production Technology has deep theoretical knowledge of applied mathematics, applied mechanics, mechatronics, biomechanics, machine control theory and artificial intelligence, experimental theory and other disciplines in his field, which allows him to scientifically search for and bring new problems and development of the Production Technology department also for practical use in production technology, robotics and other branches of the economy, where production technology, robotic equipment and production systems are used.

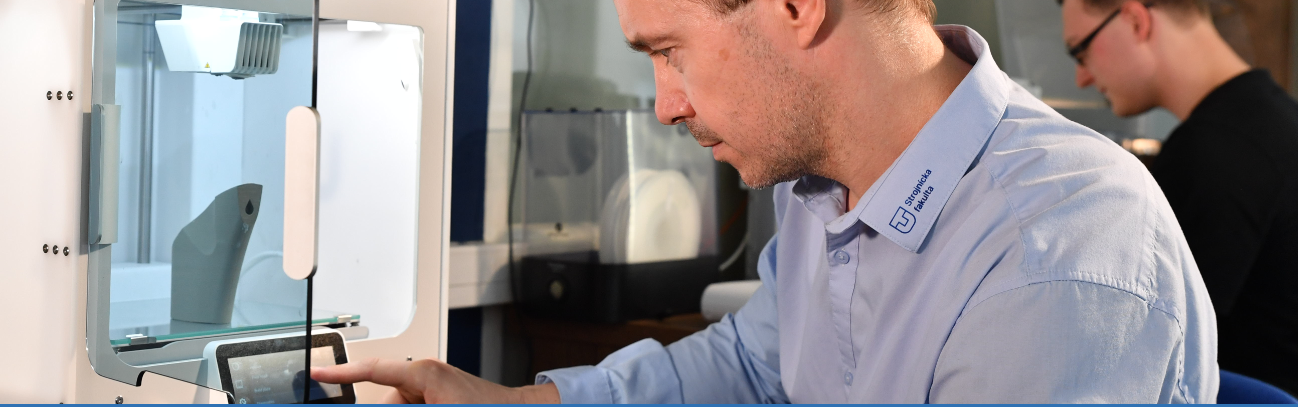

The graduate of the doctoral study program Production Technology has mastered the principles of scientific work, masters the formulation of problems, their analysis, the search for new solutions. Can mathematically model and simulate the properties of new solutions in 3D models, masters the methods of planning scientific experiments and specific methodologies of experimental verification of results obtained using analytical methods. He has also mastered the ethical principles and rules of scientific work and the presentation of the results of his activities.

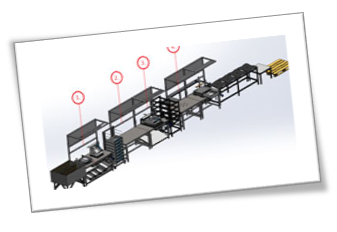

The specific specialization of the graduate depends on the topic of the dissertation and due to the breadth of the field of production technology can be directed to research and development of new production machines (machine tools, forming, welding, foundry, food, ...), robots and other production equipment, their components and modules as well as entire production systems using production technology, as well as the issues of their diagnostics, operation, maintenance and management.

APPLICATION OF GRADUATE

Graduates of the study program Production Technology (3rd degree) will find employment in the research and production spheres in all branches of engineering focused on design, engineering and construction, as well as technical diagnostics and the use of production machines, robots and production systems. It will also be used in the creation of software focused on virtual prototyping, expert systems and modeling and simulation of the properties of production machines, robots and production systems, as well as in small and medium private companies engaged in sales, design and comprehensive supply of production machines, robots and production equipment and systems. .

Graduates of the study program find employment, e.g. in the following companies:

- Manex Košice - development and production of automation handling and packaging technology,

- BWG Prešov - design and construction of automated sheet metal processing lines for the automotive industry,

- OSRAM Slovakia Nove Zámky - development and production of single-purpose machines and equipment for the production of light bulbs,

- Whirlpool Slovakia Poprad - development and production of washing machines,

- Embraco Slovakia Spišská Nová Ves - development and production of compressors for white goods,

- Ford Getrag Slovakia Kechnec - production of gearboxes for the automotive industry,

- SPINEA Prešov - production of precision gearboxes,

- PSA Trnava - car production,

- H.M.Transtech Prešov - development and production of automated workplaces for sheet metal processing,

- BSH Drives and Pumps Michalovce - development and production of electric motors for white goods,

- Johnson Controls Trenčín - development and production of components for the automotive industry.

Graduates of the study program Production Machinery and Equipment will also be employed in the field of scientific research and pedagogy. Priority in the field of university and research institutes.